Comprehensive Guide to Key Industrial Machinery in the Plastic Manufacturing Industry

This comprehensive guide explores the key industrial machinery used in plastic manufacturing, highlighting their functions, applications, and significance. It covers laser cutters, capsule fillers, blow molding machines, and PVC extruders, emphasizing their role in improving productivity, precision, and product quality. Understanding these machines is essential for manufacturers aiming to optimize their processes and stay competitive in the expanding plastic industry. The article also discusses recent advancements and maintenance best practices to ensure efficiency and quality in plastic production.

The rapid evolution and expansion of the plastic manufacturing industry are fundamentally driven by the deployment of advanced, high-efficiency industrial machinery. These specialized machines play a crucial role in streamlining production processes, boosting output, optimizing cost efficiency, and elevating the overall quality of plastic products. The diverse range of equipment used in plastic manufacturing encompasses various machines tailored to different stages of production, each serving specific functions to ensure precision and efficiency. This extensive overview aims to shed light on the major categories of plastic machinery, their applications, and their significance in modern industrial settings.

Understanding Plastic Manufacturing Equipment

The machinery utilized in plastic manufacturing is diverse and sophisticated, designed to process, shape, and assemble plastic materials into finished products. The core categories include injection molding machines, auxiliary processing units, secondary shaping tools, and compounding systems. In addition, a variety of specialized devices such as CNC routers, film blowers, vacuum formers, rotational molding machines, granulators, and shredders are integral throughout different stages of production. These machines are capable of performing precise tasks such as cutting, engraving, welding, and trimming, which collectively contribute to producing high-quality, durable plastic components efficiently.

Major Types of Industrial Machines in Plastic Manufacturing

Below are some of the most critical types of machinery employed in the industry to achieve optimal production outcomes:

1. Precision Laser Cutting Equipment

Precision laser cutters are indispensable tools in plastic processing, especially for applications requiring intricate designs and high accuracy. These devices operate through CNC (Computer Numerical Control) systems guided by CAD (Computer-Aided Design) files, allowing for detailed and precise cuts or etching on plastic sheets and components. Laser cutting technology is highly versatile, capable of working on various plastic materials such as acrylic, polycarbonate, and PVC. Whether for creating detailed signage, decorative panels, or prototype components, laser cutters facilitate complex shapes with minimal waste, thereby improving material efficiency and product fidelity. Their ability to handle both cutting and surface engraving makes them a staple in industries like advertising, industrial design, and engineering prototyping.

2. Capsule Filling Machinery

Although primarily associated with the pharmaceutical sector, capsule filling equipment also finds applicability in other sectors requiring precise filling processes. These machines automate the filling of capsules with various active ingredients, powders, or granules. They range from manual, semi-automatic, to fully automated systems designed for high-volume production lines. The process involves accurately depositing the medicament or material into empty capsules, sealing, and ejecting finished capsules for subsequent packaging. In industrial settings, high-speed capsule fillers ensure uniformity and efficiency, reducing human error and increasing throughput. Their precision and automation capabilities are crucial for maintaining quality standards in pharmaceutical manufacturing, nutraceuticals, and supplement industries.

3. Blow Molding Machines

Blow molding is a manufacturing process used to produce hollow plastic items, including bottles, containers, and tubes. The process involves heating plastic parisons (pre-forms) or extruded plastic tubing and inflating them within molds to form the desired shape. This category includes extrusion blow molding, injection blow molding, and stretch blow molding, each suited to specific product requirements. These machines are equipped with components such as extruders, mold clamping units, and blow heads. They are highly valued in packaging industries, especially in cosmetics, food, and beverage sectors, due to their ability to produce lightweight, durable, and cost-effective containers. The efficiency of blow molding machines allows for high-volume production, making them essential for brands demanding large quantities of standardized packaging solutions.

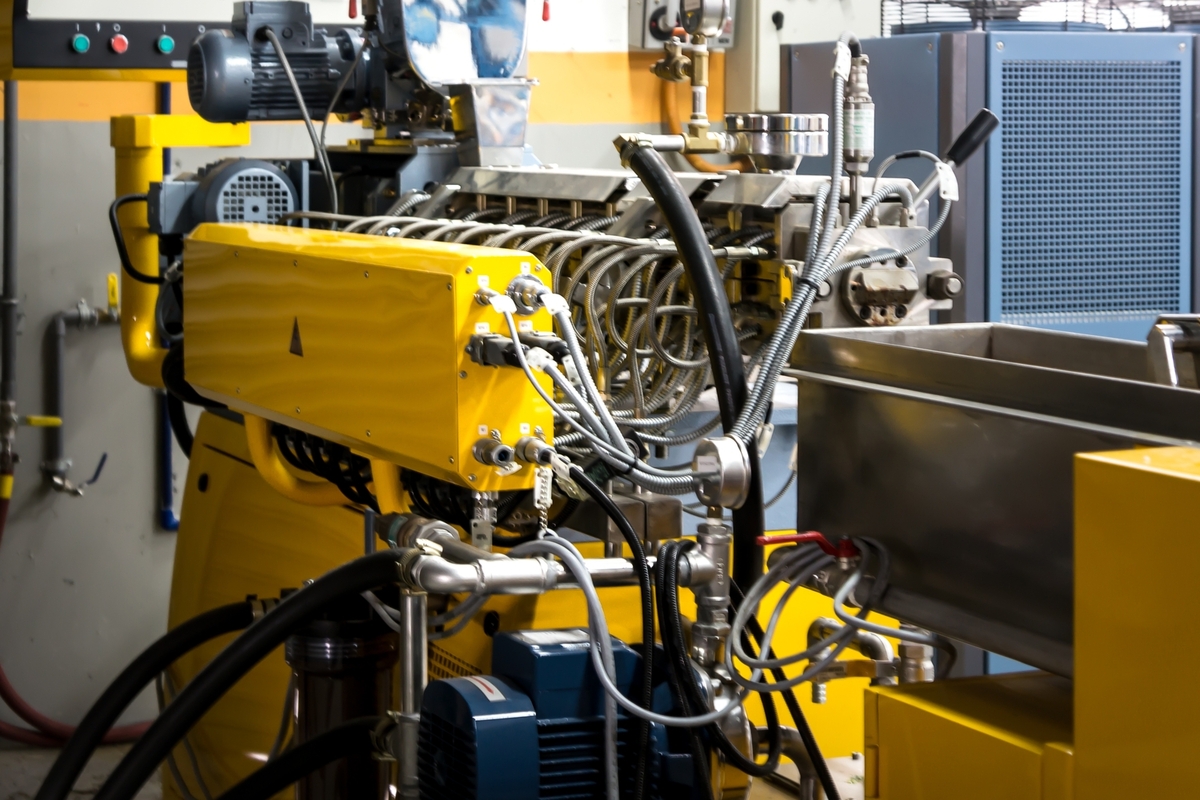

4. PVC Extrusion Equipment

Extrusion machinery dedicated to PVC is critical for creating long, continuous profiles such as pipes, window frames, and sheets. These machines work by forcing PVC resin through designated dies to form specific shapes, with the extrusion process often involving heating and cooling cycles. Single-screw and twin-screw extruders are common types, chosen based on the complexity of the profile and required production rate. The machinery incorporates features such as screw and barrel assemblies crafted from high-grade materials like high-carbon steels to withstand operational stresses. Proper calibration of temperature zones, die design, and cooling systems are essential for ensuring consistent quality and dimensional accuracy in the final products. PVC extrusion equipment supports industries ranging from construction to electronics, facilitating efficient and precise manufacturing of essential components.

As the global demand for plastic products continues to escalate across various sectors, the development and improvement of industry-specific machinery remain vital. Modern plastic manufacturing facilities emphasize regular maintenance, automation, and quality control to optimize output, minimize waste, and ensure compliance with safety and environmental standards. The evolution of machinery technology, including the integration of IoT and smart systems, promises to further enhance efficiency, transparency, and sustainability in plastic production processes. Manufacturers investing in advanced equipment and proper maintenance protocols will secure competitive advantages in this dynamic industry, ultimately delivering high-quality plastic products to meet diverse market needs.