Ultimate Guide to PVC Extrusion Equipment: Types, Features, and Pricing in Mexico

This comprehensive guide explores the various types of PVC extrusion equipment available in Mexico, detailing their features, advantages, and price ranges. Whether you're starting a new PVC manufacturing plant or upgrading your existing machinery, understanding these options will help you make informed decisions to boost production efficiency and product quality. The article covers single screw, twin screw, conical, parallel, high-speed, and compact extruders, offering insights into their optimal applications and investment considerations. Partnering with local suppliers ensures reliable support and maintenance. Designed for manufacturers looking to expand or improve their PVC extrusion capabilities, this guide is an essential resource.

Ultimate Guide to PVC Extrusion Equipment: Types, Features, and Pricing in Mexico

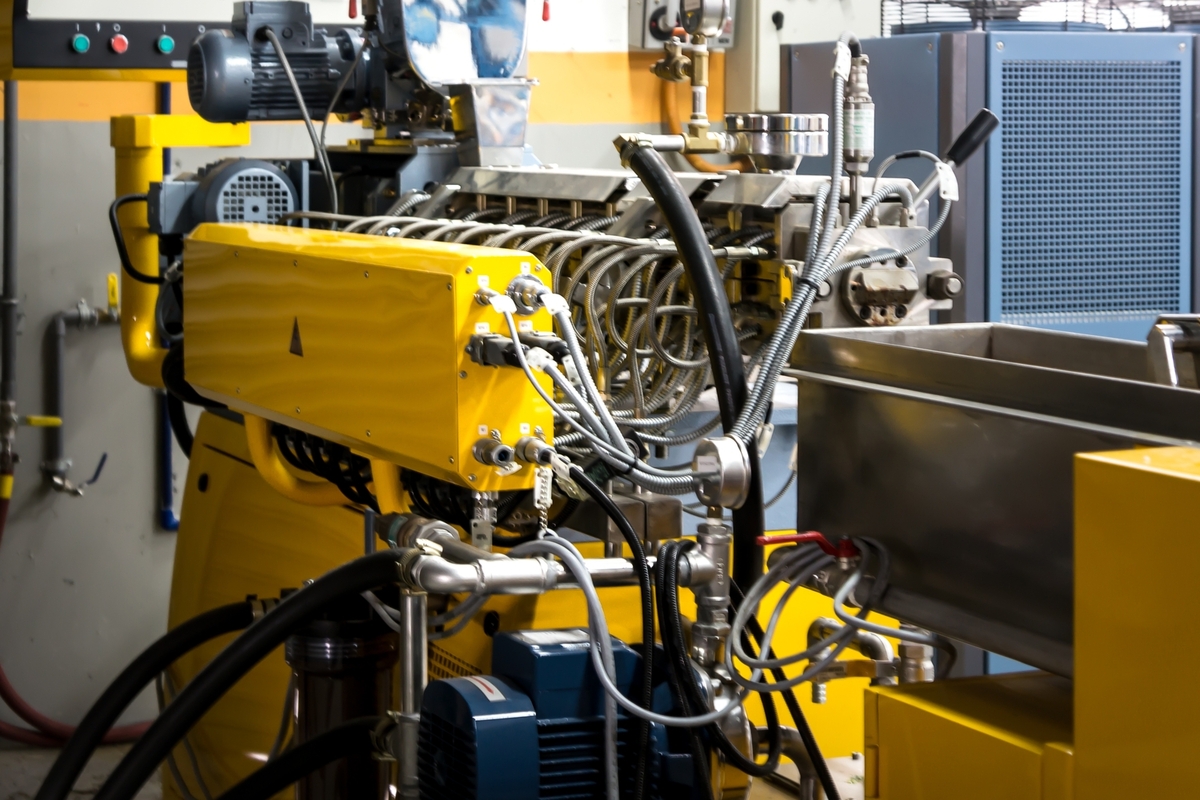

Mexico’s thriving plastics industry relies heavily on advanced PVC extrusion machinery to produce a wide range of products, including pipes, profiles, sheets, and complex composite structures. As demand for durable, high-quality PVC products continues to grow, understanding the different types of extrusion equipment available in Mexico’s market becomes essential for manufacturers, investors, and entrepreneurs aiming to optimize their production lines. This comprehensive guide offers an in-depth look at various PVC extrusion machines, their key features, advantages, cost ranges, and how to choose the right equipment tailored to your specific manufacturing needs.

PVC extrusion technology has evolved significantly over the years, providing manufacturers with versatile machinery options that can cater to small-scale localized production as well as large-scale industrial output. Whether you're launching a new PVC fabrication enterprise or upgrading existing equipment, knowing the nuances between extruder types, their functionalities, and price points will help you make informed investment decisions that enhance efficiency and profitability.

Below, we explore the most popular types of PVC extrusion machinery available in Mexico, their operational principles, benefits, along with estimated costs, and tips on selecting suitable equipment based on your production goals.

1. Single Screw PVC Extruders

Overview:

Single screw extruders are among the most common and versatile machines used in PVC processing. They consist of a single, continuous screw rotating within a heated cylindrical barrel. The screw conveys and melts raw PVC materials, which are then pushed through a shaping die to produce a variety of profiles, pipes, and sheets. They are recognized for their simplicity, cost-effectiveness, and ease of operation, making them an ideal choice for many small to medium manufacturing setups.

Advantages of Single Screw Extruders:

Cost-effective machinery suitable for basic PVC production lines.

Easy to operate, maintain, and troubleshoot, reducing downtime and operational costs.

Excellent for manufacturing standard PVC pipes, sheets, and simple profiles without complex formulations or additives.

Widely available in Mexico from reputable suppliers, ensuring easy procurement and servicing.

Price Range in Mexico:

Depending on capacity, brand, and additional features, single screw extruders typically fall within the price range of $20,000 to $80,000 USD. Smaller units or basic models on the lower end of this spectrum are suitable for startups or localized production, whereas larger, more sophisticated models with higher throughput capacity tend toward the higher end of the scale.

2. Twin Screw PVC Extruders

Overview:

Twin screw extruders feature two screws that intermesh and rotate in a synchronized manner. This configuration allows for superior mixing, better heat transfer, and enhanced handling of complex formulations. These machines are particularly well-suited for processing PVC compounds that contain multiple additives, fillers, stabilizers, or require specific compatibilities. Their design facilitates uniform dispersion of materials, critical for producing high-quality, consistent products.

Advantages of Twin Screw Extruders:

Exceptional mixing capabilities ensure homogeneity in complex PVC formulations.

High efficiency and throughput, reducing production time.

Suitable for manufacturing specialized profiles, high-grade pipes, and multi-layered sheets.

Flexible operation with adjustable parameters for different formulations.

Price Range in Mexico:

Prices for twin screw extruders generally range from $50,000 to $150,000 USD, varying based on screw design, capacity, and manufacturer reputation. High-capacity or custom-designed units, especially those integrated with advanced control systems, tend to fall within the upper price range.

3. Conical Twin Screw Extruders

Overview:

Conical twin screw extruders feature screws that are shaped conically, with a larger diameter at the feed end tapering to a smaller diameter at the discharge end. This design enhances feeding, melting, and mixing processes, particularly effective in processing large or intricate PVC products. They provide better energy efficiency and are often used for complex profiles requiring precise control.

Advantages of Conical Twin Screw Extruders:

Efficient feeding and melting, suitable for high-viscosity or complex compounds.

Ideal for large-diameter pipes, profiles, and specialty PVC products.

Lower energy consumption due to optimized heat transfer.

Good for producing uniform, high-quality finished products.

Price Range in Mexico:

Typically priced between $60,000 and $180,000 USD, depending on size, brand, and technological features. The conical design makes them a preferred choice for manufacturers dealing with demanding specifications and high-volume production.

4. Parallel Twin Screw Extruders

Overview:

Parallel twin screw extruders have two screws oriented parallel to each other, rotating in the same direction. This setup ensures uniform material flow, high dispersion, and consistent quality. They are highly reliable and capable of processing a broad range of PVC formulations, especially when producing premium products such as high-grade profiles, sheets, and complex hollow sections.

Advantages of Parallel Twin Screw Extruders:

Ensure reliable and stable operation during long production runs.

Deliver high-quality, uniform products with excellent dispersion of additives.

Suitable for high-volume manufacturing of sophisticated PVC components.

Energy-efficient with advanced control systems for precise operation.

Price Range in Mexico:

Prices typically vary from $70,000 to $200,000 USD, depending on the capacity, features, and technological sophistication. Investment in high-end models may include additional automation and control options for maximum productivity.

5. High-Speed PVC Extruders

Overview:

High-speed PVC extruders are engineered for mass production, combining innovative technology, powerful motors, and optimized process control to maximize output rates. These machines are ideal for large-scale manufacturing facilities aiming to meet high demand without compromising quality.

Advantages of High-Speed Extruders:

Massive production capacity suited for industrial-scale operations.

Precise control systems ensure consistent quality at high speeds.

Reduced cycle times, making production more efficient.

Capable of producing a wide variety of PVC products rapidly.

Price Range in Mexico:

Prices range from $100,000 to $300,000 USD, primarily depending on the speed, automation level, and technological features integrated into the extruder. Higher-end models equipped with the latest features represent better long-term investment for extensive production facilities.

6. Compact PVC Extrusion Equipment

Overview:

Designed for smaller factories, startups, or facilities with constrained space, compact PVC extrusion machines offer space-saving design without sacrificing essential functionality. These units are scalable for medium production volumes and are favored for their ease of installation and maintenance.

Advantages of Compact Machines:

Space-efficient, ideal for facilities with limited space.

Lower initial investment costs.

Fast setup and simple operation, reducing training time.

Suitable for medium-scale production requirements.

Price Range in Mexico:

Typically priced between $15,000 and $50,000 USD, with variations based on capacity, automation features, and customization options. These units are excellent choices for emerging businesses or those seeking modular expansion.

In summary, selecting the appropriate PVC extrusion machinery in Mexico depends on multiple factors such as production volume, product complexity, budget, and technological requirements. Partnering with reputable local suppliers ensures access to quality equipment, reliable support, and maintenance services. By understanding the differences in machine types, their capabilities, and price points, manufacturers can make prudent investments that improve efficiency, product quality, and competitiveness in the industry.

Note:

All price ranges mentioned are estimates and can vary based on market fluctuations, customization preferences, and supplier conditions. Always consult with local manufacturers or authorized distributors for precise, up-to-date pricing and suitable options tailored to your specific needs. This article aims to serve as an informational resource for those interested in the Mexican PVC machinery market; however, professional consultation is recommended prior to purchasing any equipment.