Comprehensive Guide to Power Connectors: Top Brands and Selection Tips

This comprehensive guide delves into power connectors, highlighting their vital functions, types, and key brands. It offers insights into selecting the right connectors for various industrial and electronic applications, emphasizing safety, durability, and performance. Designed for engineers, technicians, and enthusiasts, this article provides an in-depth overview of best practices and top market leaders in power connector technology.

Comprehensive Guide to Power Connectors: Top Brands and Selection Tips

Power connectors play a critical role in modern electronics, serving as the essential link that ensures reliable transfer of electrical energy from power sources to various devices. These components are fundamental in both everyday consumer electronics and complex industrial systems. Whether you're designing a new electronic device, maintaining industrial machinery, or upgrading automotive systems, understanding the different types of power connectors, their functions, designs, and leading brands is vital for optimal performance and safety.

Understanding Power Connectors

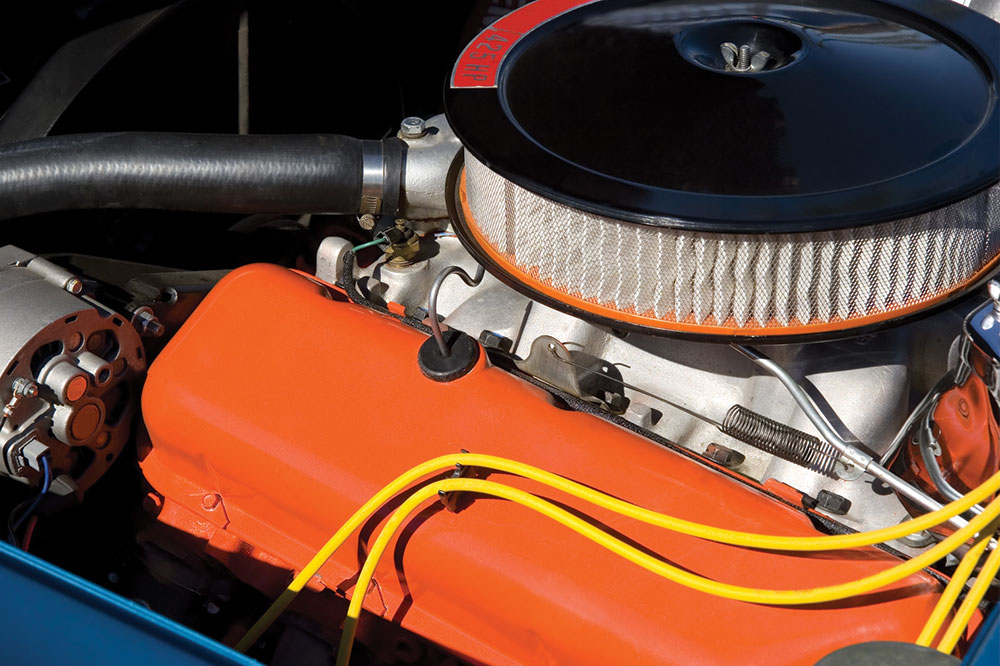

Power connectors are specialized electronic components designed to facilitate the safe and efficient transfer of electrical current. They are used to connect power supplies to electronic devices, ensuring consistent power delivery. These connectors come in a wide variety of types, sizes, and configurations tailored to meet specific application requirements. They are engineered to handle both Direct Current (DC) and Alternating Current (AC), making them versatile for use in batteries, automotive systems, industrial machinery, and household appliances.

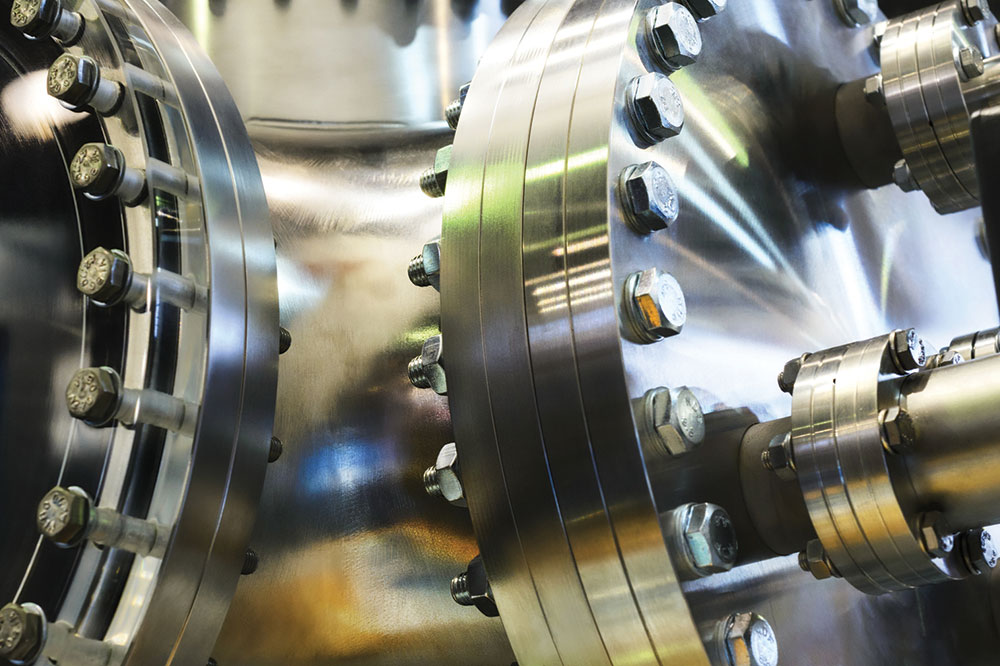

In essence, power connectors are the gateways that link power sources to electronic circuits, enabling devices to operate reliably. They are engineered with features to resist environmental factors such as water, dust, shock, and vibration, especially for industrial and automotive environments where durability is crucial.

Types of Power Connectors and Their ApplicationsThere exists a broad spectrum of power connectors, each tailored for specific applications and operational conditions. The primary classification is based on connection durability—permanent or removable—and environmental robustness. For instance, some connectors are designed for quick disconnection in consumer electronics, while others are mounted permanently in industrial setups for long-term operation.

Among the common types are IEC power connectors used widely in household appliances, circular connectors often employed in industrial settings, and Molex connectors frequently found in automotive and computer systems. Each type features particular design elements such as pin counts, contact arrangements, and locking mechanisms to prevent accidental disconnections.

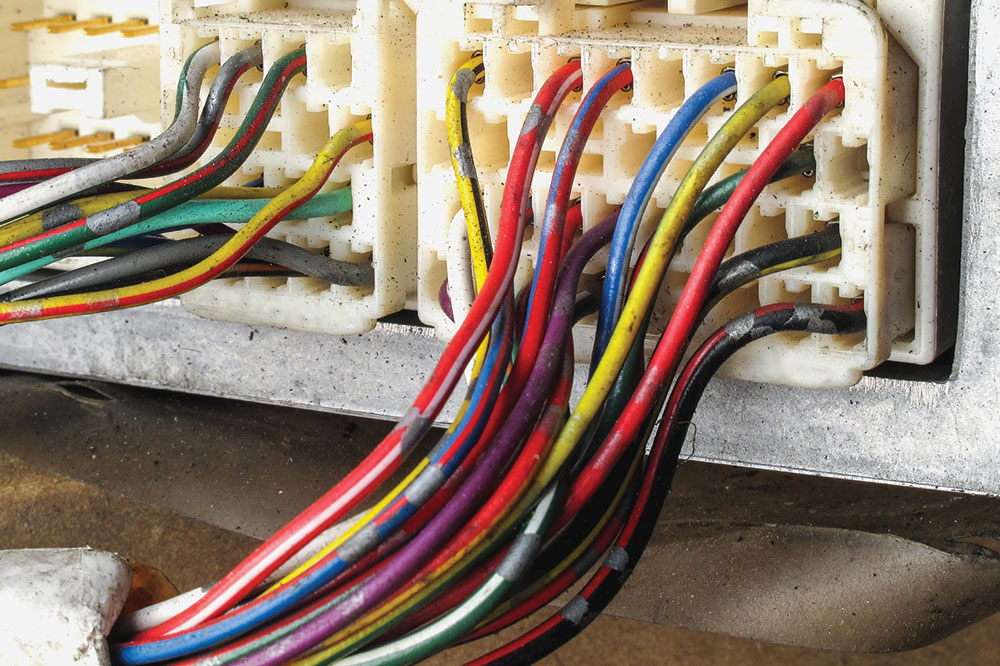

Pin Configuration and Connection PrinciplesProper pin configuration and connection setup are critical aspects that influence the functionality and safety of power connectors. Ensuring the correct alignment of pins relative to their mating counterparts helps prevent electrical faults and mechanical damage. Manufacturers specify detailed pinouts, which must be adhered to during installation or integration.

Typical connection methods include soldering, crimping, and wire wrapping, each suited for different manufacturing or repair scenarios. Selecting connectors with appropriate pin configurations not only ensures electrical compatibility but also enhances operational reliability and reduces the risk of failures.

Core Components of Power ConnectorsPower connectors are composed of various mechanical and electrical parts, each serving a specific purpose. The main parts include blades, pins, sockets, jacks, and plugs. These elements are designed to ensure secure mating, proper alignment, and reliable electrical contact. Many connectors feature keying mechanisms to prevent incorrect insertion, which could lead to short circuits or damage.

In addition, robust mechanical features such as locking latches, strain reliefs, and weatherproof seals are incorporated to enhance durability, especially in rugged environments. Selecting the right components based on environmental conditions and operational requirements is essential to maintain safety and functionality over time.

Leading Brands in Power ConnectorsThe market for power connectors is highly competitive, featuring numerous reputable brands that offer a wide range of high-quality products. These industry leaders have established their reputation through innovation, reliability, and compliance with international standards.

Some of the most prominent power connector brands include:

J.S.T: Known for their extensive range of connectors suitable for consumer electronics, automotive, and industrial applications.

JAE: Renowned for precision and high-reliability connectors used mainly in aerospace and medical equipment.

Aptiv: A global leader offering innovative power and data connector solutions for automotive and industrial sectors.

Yazaki: Specializes in automotive wiring harnesses and power connectors with a focus on durability and safety.

These brands are recognized for their commitment to quality, technological advancement, and compliance with safety standards. When selecting power connectors, it is advisable to choose products from these manufacturers for their assurance of performance and longevity.

In conclusion, understanding the diverse types of power connectors, their components, and leading brands is key to making informed decisions that ensure safety, efficiency, and durability. Whether for industrial uses, automotive applications, or consumer electronics, choosing the right power connectors is essential for the optimal functioning of your electrical systems.