Comprehensive Guide to Materials Essential for High-Performance Air Filtration

Discover the essential materials powering modern air filtration systems. From activated carbon to electrostatic fabrics, learn how these components improve air quality across various industries. This comprehensive guide explores their properties, applications, and recent technological advancements, helping you choose the optimal filtration solutions for cleaner, healthier environments.

Key Materials Utilized in Advanced Air Filtration Systems

Air filtration technology is a cornerstone of maintaining healthy indoor and outdoor environments by effectively removing airborne pollutants such as dust, bacteria, viruses, and harmful gases. These systems are integral not only in residential and commercial buildings but also in specialized applications like aircraft engines, clean rooms, and industrial facilities. Over recent decades, significant advances in materials science and engineering have led to the development of highly efficient air filters, capable of capturing even microscopic contaminants while minimizing resistance to airflow. Understanding the diverse range of materials used in these systems is crucial for selecting the right filtration solutions tailored to specific needs.

Filter components are designed based on application requirements, environmental conditions, and performance expectations. The selection of appropriate materials directly influences the effectiveness, durability, and maintenance of air filtration systems. With innovations driven by breakthroughs in aerodynamics and nanotechnology, modern filters incorporate a variety of high-performance materials to meet the increasing demand for cleaner air.

Airborne particle composition varies significantly depending on environment and application, necessitating customized filter material selection to achieve optimal air quality outcomes. The most commonly employed filter materials include:

Activated Carbon: Activated carbon, derived from charcoal, is one of the most frequently used materials in air filtration due to its exceptional ability to adsorb odors and gaseous pollutants such as ozone, volatile organic compounds (VOCs), and other harmful gases. Its porous structure provides a large surface area for adsorption, making it effective in both residential odor control systems and industrial pollution management.

Polyurethane Foam: Known for its density and durability, polyurethane foam has historically been used in high-performance filters, including in rugged environments such as rally cars. Its porous structure efficiently traps larger airborne particles like dust and debris. However, advances in filter technology are gradually replacing traditional foam with newer, more effective materials.

Electrostatic Materials: These materials generate static electricity to attract and trap airborne particles, significantly increasing filtration efficiency. Electrostatic filters, including ionizer-based systems, are particularly effective in capturing fine particles, including allergens and microscopic pollutants, making them suitable for sensitive environments like hospitals and cleanrooms.

Stainless Steel Mesh: Offering durability and reusability, stainless steel mesh filters are available in various mesh sizes to provide different levels of filtration. They are ideal for industrial applications where longevity and the ability to clean and reuse are critical, such as in HVAC systems and air purification units.

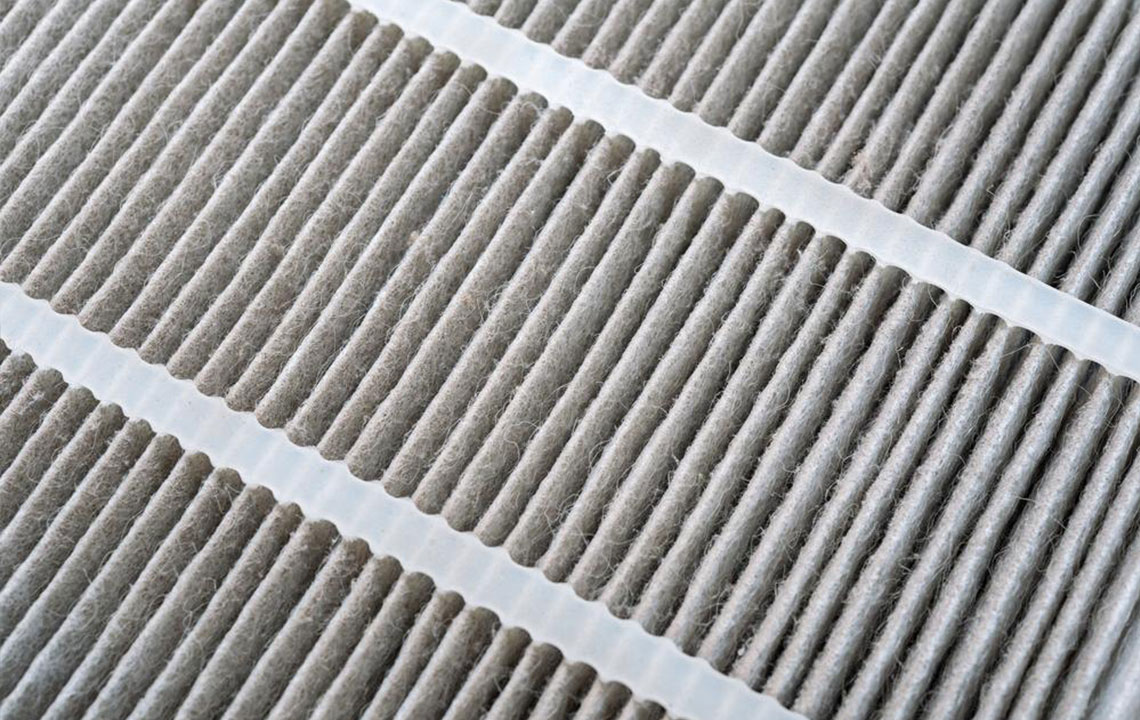

Paper and Fibrous Media: Widely used due to their low cost and ease of manufacturing, paper filters—often pleated to increase surface area—are common in automotive air filters and residential HVAC systems. They are highly effective for capturing larger particles but may require frequent replacement depending on environmental conditions.

Cotton: Emerging as an alternative filtering material, cotton possesses a natural fibrous structure capable of trapping particulate matter. Although its usage remains limited, it is appreciated in certain applications like air compressors and custom filtration solutions owing to its eco-friendly nature and effective filtration properties.

Hybrid and Other Materials: Modern filters often combine several materials such as polyester, oil baths, or water-based filters to enhance overall filtration performance, extend lifespan, and address specific contaminant types. The choice of materials depends on factors like cost-effectiveness, desired filtration levels, airflow resistance, and specific application needs.

In summary, selecting the right filtration material is a critical step toward achieving high air quality, whether for industrial, commercial, or residential purposes. Continuous research and technological advancements are expanding the library of available materials, promising even more efficient, durable, and environmentally friendly air filtration solutions in the future.