Ultimate Guide to Purchasing Industrial Air Compressors in Mexico: Expert Tips for Efficient Selection

This comprehensive guide provides expert insights for selecting the ideal industrial air compressor in Mexico. It covers application needs, technical specs, reliability tips, maintenance, energy efficiency, and compliance to help you make wise investment decisions, optimize operational efficiency, and ensure long-term profitability in various industrial sectors.

Ultimate Guide to Purchasing Industrial Air Compressors in Mexico: Expert Tips for Efficient Selection

Choosing the perfect industrial air compressor in Mexico is a critical decision that can significantly impact your operational efficiency, safety standards, and overall productivity. With a wide range of models, features, and brands available in the Mexican market, understanding what to look for can be overwhelming. This comprehensive guide aims to provide you with detailed insights and practical advice to help you select the most suitable air compressor tailored to your specific needs, whether you’re involved in manufacturing, construction, automotive, or other industrial sectors. We will explore essential considerations including your application requirements, technical specifications, reliability factors, maintenance ease, energy efficiency, and compliance with Mexican regulations.

Understanding Your Specific Needs

Before making any purchase, it’s vital to clearly understand what your operations demand. An air compressor is a significant investment, and selecting the wrong type can lead to inefficiency, unnecessary costs, and downtime. Here are the key factors to evaluate:

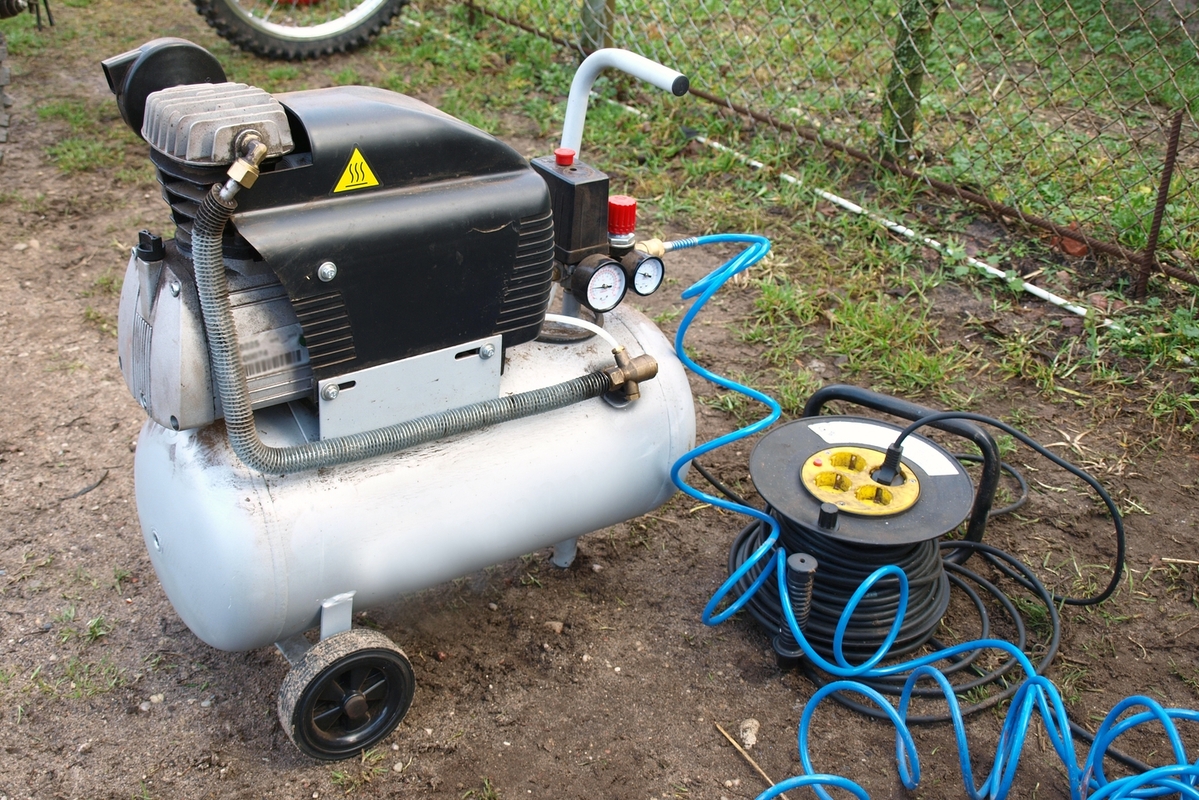

Application Type: Determine whether the compressor will serve industrial, commercial, or personal use. Heavy-duty, continuous-operation models are ideal for large-scale manufacturing plants, construction sites, and automotive assembly lines. Conversely, lighter, portable models may suffice for small workshops, home garage setups, or occasional tasks.

Power Source Compatibility: Consider the availability of power sources in your facility or job site. Options include electric-powered compressors, gasoline engines, or diesel models. Electric compressors are generally cleaner and quieter, suitable for indoor environments or where electricity is reliable. Gasoline and diesel units offer mobility and independence from electrical sources, making them ideal for remote or outdoor applications.

Portability Needs: Decide whether a stationary or portable compressor better fits your requirements. Stationary units are typically larger, more powerful, and installed in fixed locations, often integrating into your existing infrastructure. Portable models, on the other hand, are designed for mobility, enabling you to move the equipment easily across different job sites or within a workshop.

Variety of Compressor Types Explained

Understanding the various types of air compressors available in the market is crucial to making an informed choice. Each type has its advantages and limitations, depending on your operational demands:

Reciprocating Compressors: These are among the most common and versatile air compressors, typically featuring a piston mechanism. They are cost-effective, reliable, and suitable for both small-scale applications and larger industrial uses when configured in multi-stage setups. They can deliver high-pressure air and are ideal for tasks requiring precise air delivery.

Rotary Screw Compressors: Known for their robust design, rotary screw compressors provide continuous operation and high efficiency. They are preferred in manufacturing plants and industries where constant airflow is necessary. They usually come with lower maintenance requirements and longer service life.

Centrifugal Compressors: These are high-capacity units designed for large-scale industrial applications with significant airflow requirements. They operate at high speeds and are more complex and costly than reciprocating or rotary screw models. Suitable for power plants, large refineries, and other demanding environments.

Critical Technical Specifications to Focus On

Selecting an air compressor also involves scrutinizing key technical parameters to ensure optimal compatibility with your work:

CFM (Cubic Feet per Minute): This measures airflow capacity. To prevent bottlenecks, choose a compressor with a CFM rating that matches or exceeds your tools’ requirements, ensuring smooth operation.

PSI (Pounds per Square Inch): This reflects the pressure the compressor can generate. Heavy-duty industrial tasks typically demand higher PSI levels, so verify that your compressor can accommodate these pressures effectively.

Tank Capacity: Larger tanks store more compressed air, enabling longer periods of operation without needing to restart the unit. For continuous or high-demand applications, a bigger tank can significantly enhance efficiency and reduce wear on the compressor.

Prioritizing Reliability and Durability

Since an industrial air compressor represents a considerable investment, durability and reliability should be at the forefront of your decision:

Brand Reputation: Opt for reputable brands known for quality, performance, and reliable after-sales service in Mexico. Brands with established service networks minimize downtime due to repairs or part replacements.

Warranty and Support: Longer warranty periods often indicate higher confidence in the product’s durability. Also, check the availability of local service centers and spare parts in Mexico, which can be crucial during maintenance.

Build Quality: Select models constructed from durable materials like high-grade steel or aluminum, designed to withstand harsh industrial environments and regular usage.

Ease of Maintenance and Spare Parts Availability

Routine maintenance and quick access to spare parts are vital for maximizing your compressor’s lifespan and operational uptime:

Maintenance Requirements: Some compressors require frequent oil changes, filter replacements, or other upkeep. Ensure your team is prepared or that maintenance services are readily available.

Accessibility of Spare Parts: Choose brands that provide easily available replacement parts in Mexico. This reduces downtime and ensures your operations continue smoothly without prolonged halts.

The Significance of Energy Efficiency

Energy-efficient models help lower ongoing operational costs and reduce environmental impact:

Efficiency Ratings: Look for compressors with high energy efficiency standards, which can significantly decrease electricity bills over time.

Variable Speed Drives (VSD): VSD technology allows the compressor motor to adjust its speed based on demand, conserving energy during lower usage periods and optimizing performance during peak times.

Cost Considerations and Budget Planning

Balance your initial investment with long-term operational costs:

Initial Purchase Cost vs. Operational Expenses: Cheaper models may save money upfront but could incur higher maintenance, energy, or repair costs later. Investing in higher-quality systems can be more economical in the long run.

Leasing vs. Buying: For short-term projects or limited budgets, leasing equipment might be a practical option, allowing access to newer models without a large initial expenditure.

Ensuring Regulatory Compliance and Certifications

Compliance with Mexican safety, environmental, and quality standards is essential:

Certifications: Verify that the compressor complies with local standards such as NOM (Normas Oficiales Mexicanas) certifications to ensure safety and environmental protection.

Import and Duty Considerations: When sourcing internationally, be aware of import taxes, tariffs, and customs procedures that might add to your overall costs.

In conclusion, selecting the right industrial air compressor in Mexico demands a strategic approach grounded in understanding your specific operational needs, technical specifications, reliability factors, maintenance considerations, and compliance requirements. Adequate research and careful planning will ensure you invest in equipment that enhances productivity, complies with local regulations, and provides long-term cost savings. An informed purchase leads to smoother operations, lower downtime, and better return on investment, supporting your business goals effectively.