Comprehensive Guide to Snow Plow Storage for Prolonged Equipment Life

Proper snow plow storage is essential for maintaining equipment longevity and performance. This comprehensive guide offers detailed tips on cleaning, protecting, and preserving your plow post-winter, including storage location, lubrication, hydraulic maintenance, tension adjustment, and protective coverings. Implementing these best practices will minimize damage, reduce repair costs, and ensure your snow removal equipment is ready for the upcoming season. Proper storage is a small investment of time that pays off with years of reliable performance, preventing rust, corrosion, and mechanical failures. Keep your snow plow in excellent condition for every winter.

Comprehensive Guide to Snow Plow Storage for Prolonged Equipment Life

As the winter season comes to a close, it becomes essential for snow removal professionals, landscaping crews, and homeowners alike to take proper care of their snow plowing equipment. Proper storage after the snow season not only safeguards your investment but also ensures your equipment remains in optimal condition, ready for the next snowfall. Incorrect storage methods can lead to rust, corrosion, and mechanical issues that might result in costly repairs or replacement. Therefore, understanding the best practices in snow plow storage is vital for extending the lifespan of this critical winter tool. This comprehensive guide reviews essential tips and considerations for storing your snow plows efficiently and effectively, ensuring they maintain their performance every season.

One of the foundational steps before storage is thorough cleaning. Removing all snow, ice, salt residue, dirt, and debris from the plow surface and components is critical. Salt, while necessary during snow removal, is highly corrosive and can accelerate rusting if left on metal parts. Using a high-pressure washer or cleaning solution specifically designed for metal equipment can help eliminate stubborn grime and salt deposits. Once cleaned, dry all parts meticulously to prevent moisture retention that could cause corrosion over time.

Store your snow plow in a sheltered, elevated location rather than leaving it exposed to the elements. A garage, shed, or covered warehouse provides protection from moisture, UV rays, and temperature fluctuations, all of which can degrade materials. Elevating the plow prevents direct contact with standing water or snow that might accumulate on the ground, reducing the risk of rust and blade deterioration.

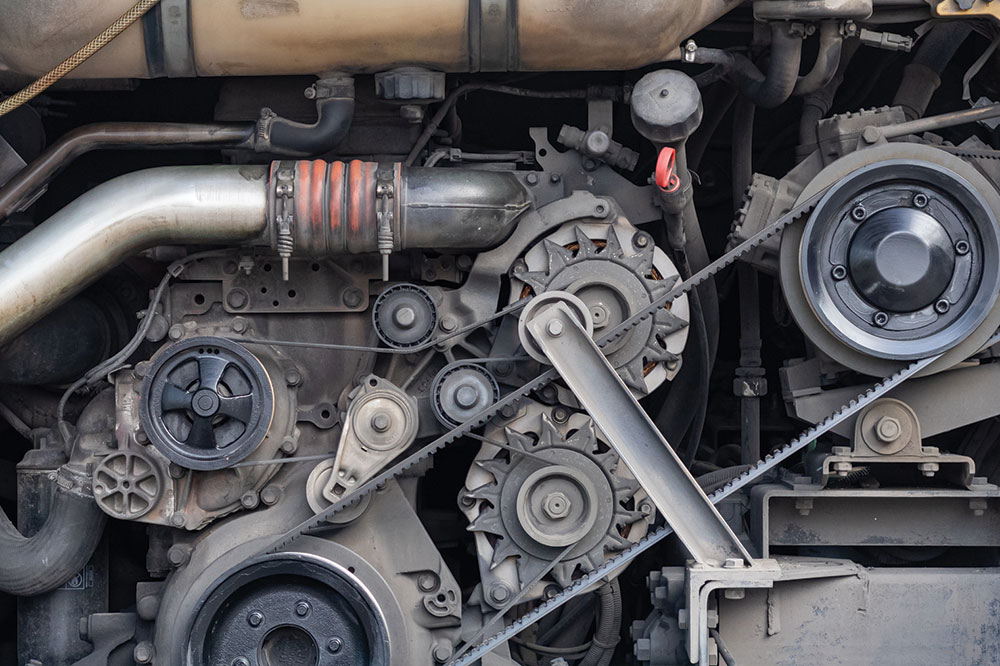

Protective measures extend beyond just storage location. Applying a coat of grease or corrosion inhibitor to vulnerable parts further shields the equipment. Focus on exposed chrome and metal surface areas such as angle cylinders, lift cylinders, and pivot points. When greasing hydraulic components, it is best to compress the lift cylinder to ensure even distribution of lubricant over all surfaces. Regular lubrication is key to preventing internal corrosion and maintaining smooth operation.

Hydraulic fluid maintenance is equally important. Before storing your snow plow, drain old hydraulic fluid, especially if it has been used extensively during the season. Old fluid can contain moisture, dirt, and other contaminants that may cause internal corrosion or degrade system performance. Refill with fresh hydraulic fluid compatible with your equipment's specifications, unless your model operates without hydraulics. Proper hydraulic fluid maintenance ensures that seals and cylinders remain in good condition for a seamless start-up when the season resumes.

Adjusting spring tension is a critical step to ensure the longevity of the plow's trip springs. These springs are designed to absorb impact and prevent damage during plowing. During storage, verify that the tension is tight enough that only a business card can pass between the springs. Proper tension prevents the springs from becoming overstressed or too loose, which could compromise their functionality over time.

Additional storage tips include covering the plow with weatherproof tarps or shrink wraps designed for outdoor equipment. This extra layer of protection guards against dust, pests, and moisture intrusion. Regular inspections during storage periods can help identify early signs of rust or damage, allowing for timely intervention before the next winter season.

In summary, implementing these best practices will significantly extend the operational life of your snow plow. Proper cleaning, storage in a sheltered, elevated space, lubrication, hydraulic fluid management, and tension adjustments contribute to a maintenance routine that minimizes repairs and enhances reliability. When stored correctly, your snow plow will be ready to perform efficiently, saving you money and reducing downtime every winter season. Investing time in proper storage preparations now ensures your equipment remains dependable and in top condition when snow begins to fall again.